As a result of living far away from home for an extended period of time during college and while working, I really had to consider what items I could hold onto while moving from place to place. The scale and physicality of projects that I could take on were severely limited pushing most of my creativity into computer-based projects.

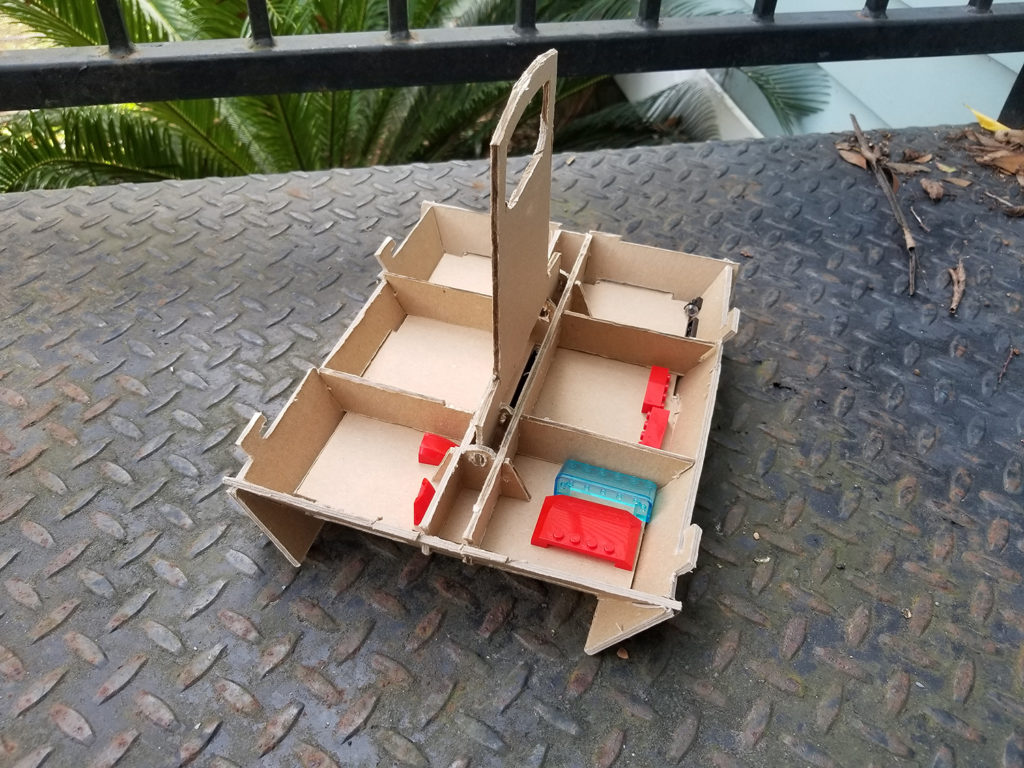

As someone who loves to build things, I wanted to make an organizer that could be easily manufactured requiring no fasteners or glue for easy storage while not in use. If there is not enough room to travel with it you can give it away or recycle. It can always be laser cut or cut from a template in the next location. The two position handle makes it possible for each box to be used individually or to nest up to two more boxes into one kit, giving it scalability to meet the current need.

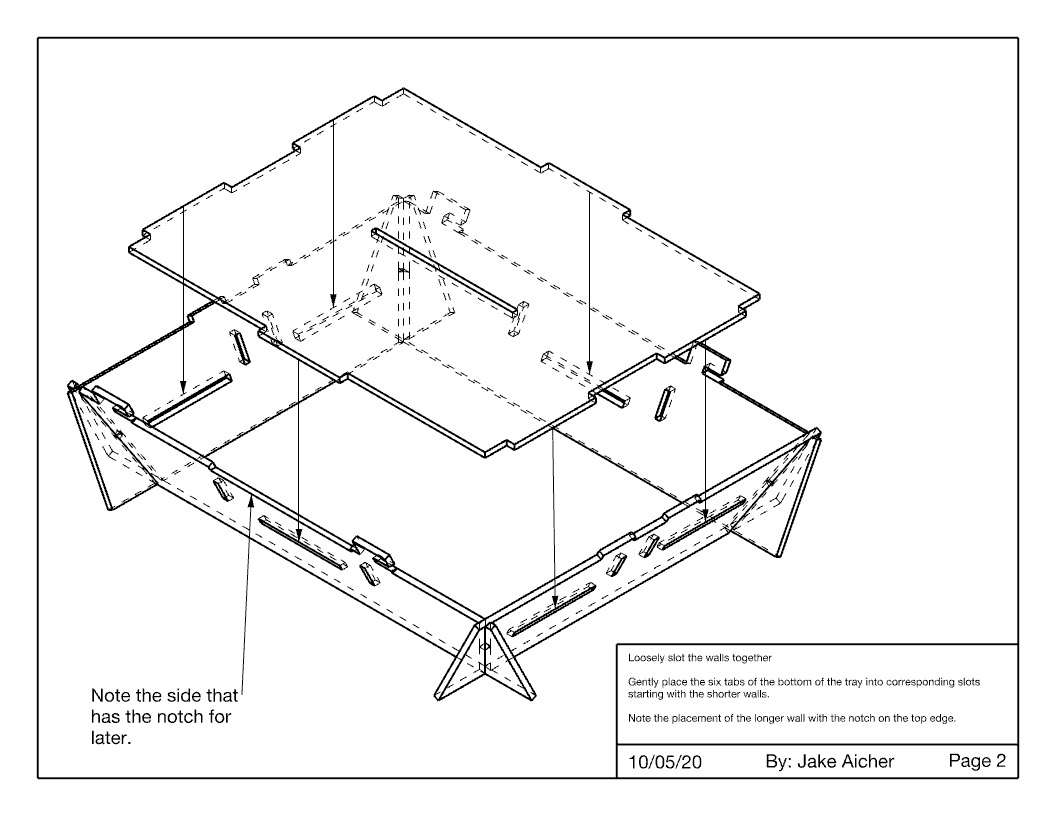

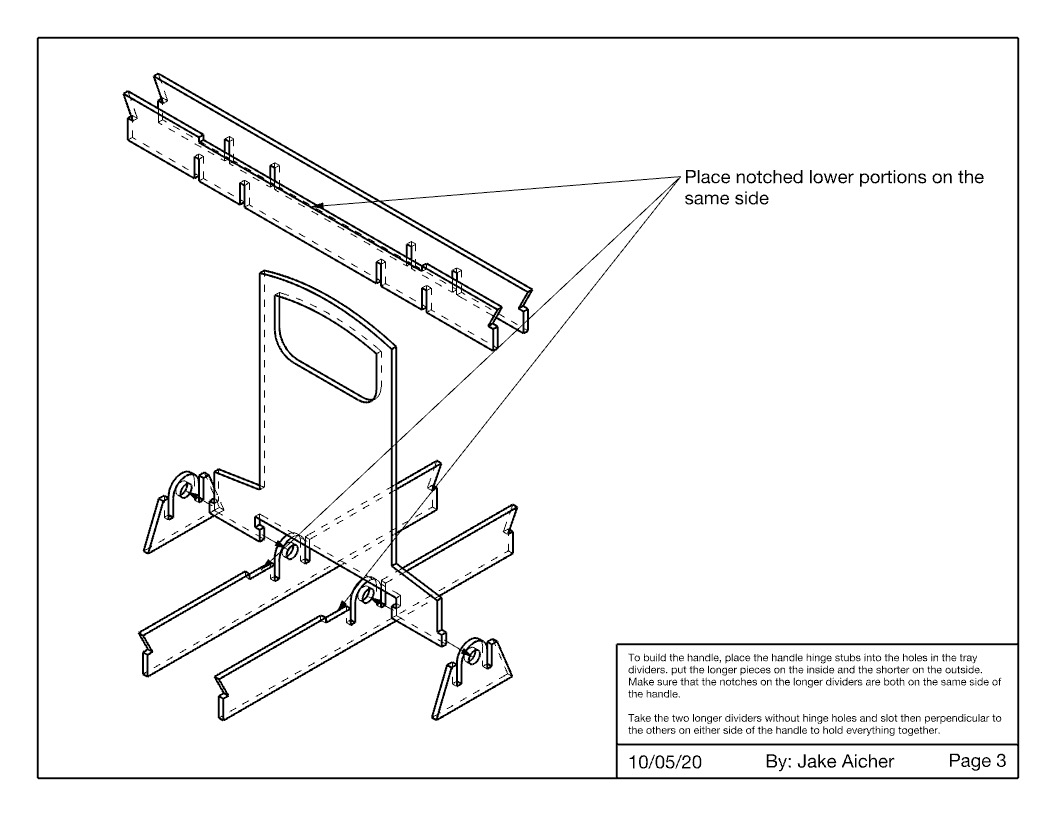

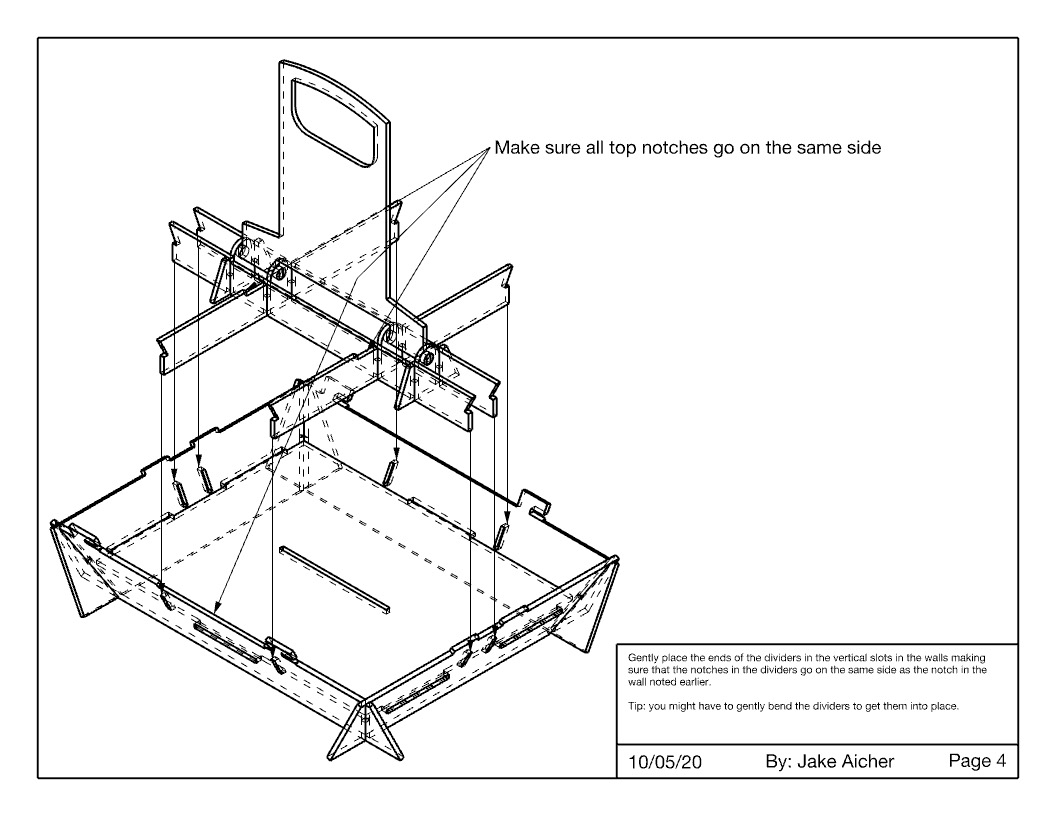

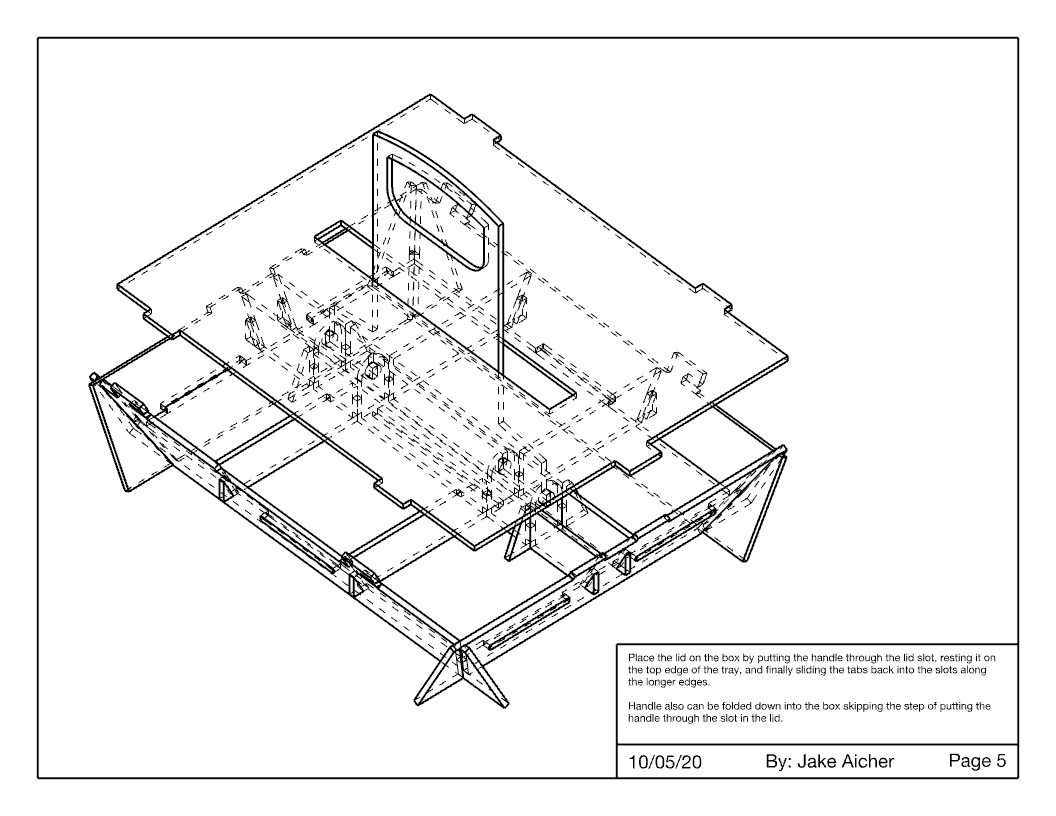

Assembly Instructions

Each tray consists of 13 pieces and can be laser cut on one 22” x 16 “sheet of material and assembled without any glue or adhesives using tabs and grooves.

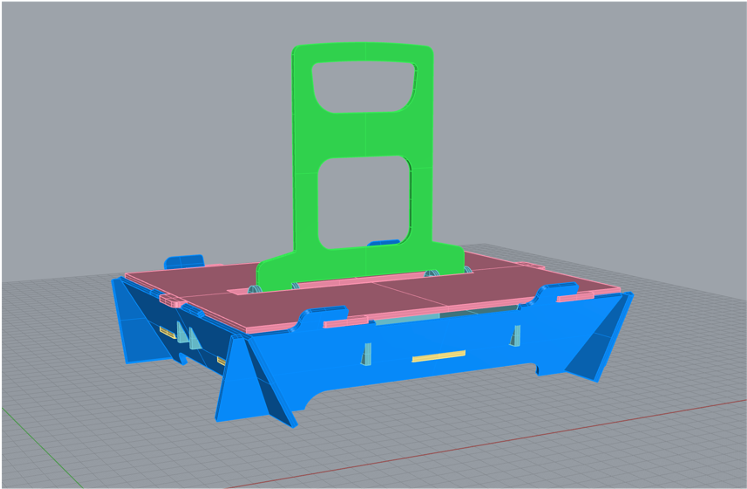

Rhino Model

The tray can be carried on its own using the handle in its folded down position or two more trays can be stacked on the handle of another for easy consolidation and transportation when the handle is in the upright position.

Grasshopper

The problem with a typical destructively modeled laser cut using slots and grooves is that they are fixed sizes that are not easily changed. When you need a container on-the-go, you don’t want to be searching for a material with the perfect thickness to fit the fixed slots.

To solve this, I created a Grasshopper definition to adjust the slots automatically by inputing the thickness of the material so you can use whatever material you can find.

Sketches and Prototype